Festool OF 1010

Plunge Router

by

25 Jan 2009

The last thing we're going to talk about on the top of the router is the spindle and collet assembly. The spindle on the OF 1010 can be locked by depressing the green button in the photo at left, thereby making bit changing a one wrench operation. In the photo I've turned the spindle so you can see the hole that the lock bar will fit into. To lock the spindle put pressure on the button and twist the spindle by grabbing the collet and rotating it. If you do this with your fingers (I usually do) be careful not to cut yourself on the bit. With pressure on the button, once the hole lines up with the bar it will slip in and the spindle will be locked.

The OF 1010 is supplied with two collets (left), sized at 1/4" and 8mm. These collets are of the self releasing style so the sleeve and the nut are attached into one assembly (right). To remove a bit you have to loosen the collet twice. With the spindle locked you loosen the collet by turning counterclockwise. This is where the nut is the tightest. Once the nut feels like it is loose you have done exactly that, loosened the nut but the sleeve is still wedged in the spindle and the bit will not come out so keep loosening the nut until you feel it get tight again, then loose. At this point the bit can be removed. What happened was the nut needs to be loosened until it starts pulling the sleeve out of the spindle, then finally when the sleeve is free the nut feels loose again and the bit can be removed.

You veterans know all about this but I explained it because I cant tell you how many times I see folks pleading for help removing a bit from their brand new router and you guessed it, it is usually because they haven't released the sleeve on their self releasing collet.

I've added the photo at right simply to show those not familiar with 8mm bits just how large they are. Here you see an 8mm and 1/4" bit and the difference in shaft size is pronounced. My original intent was to use 8mm bits in this router but I've not been able to find a reasonably priced source. As a hobbyist I cant justify spending $50 or $60 minimum on every bit though I'm sure those who do this for a living can. Festool is the largest supplier of 8mm bits that I could find.

And for those who have been clamoring for a 1/2" collet for this router, it ain't gonna happen! The spindle on the OF 1010 is just too small in diameter to accept a 1/2" collet so there's no way Festool is going to be able to supply just a 1/2" collet. They would need to redesign the router in order to accommodate a larger motor and spindle. Just buy the OF 1400 if you want 1/4-1/2" bit capability.

We're now going to look at the bottom of the router. The OF 1010 comes standard with a phenolic Base Runner covering the base plate and the standard Cover Ring installed. The Base Runner is the brown material and the Cover Ring is the black plastic ring shown in the photo at left. To remove either you will need either a star bit or a flat bladed screwdriver. If you own a Festool Toolie then you have the required size star bit.

Festool sells a number of accessory runners and includes two other rings with the OF 1010.

Let's

remove the two screws so that we can take the Cover Ring off and I can show you

the dust shroud. With the screws removed the Cover Ring just pops off

(left) which allows us to twist the clear plastic dust shroud and remove it.

Let's

remove the two screws so that we can take the Cover Ring off and I can show you

the dust shroud. With the screws removed the Cover Ring just pops off

(left) which allows us to twist the clear plastic dust shroud and remove it.

There's no need to remove it now but I just wanted to show you what it looked like. It is actually comprised of two pieces as the cover pops off. I reinstalled it so that we could install the next piece.

Like

the OF 1400 the 1010 has a Chip Catcher but this one is completely made from

plastic. It installs in the same place as the ring but also covers up the

square vacuum port. This Chip Catcher, or more accurately chip deflector,

is used during edge treatment operations and can rotate 360° around the bit.

It actually works pretty well forcing more chips up through the vacuum and

deflecting those that don't make it so they don't travel too far.

Like

the OF 1400 the 1010 has a Chip Catcher but this one is completely made from

plastic. It installs in the same place as the ring but also covers up the

square vacuum port. This Chip Catcher, or more accurately chip deflector,

is used during edge treatment operations and can rotate 360° around the bit.

It actually works pretty well forcing more chips up through the vacuum and

deflecting those that don't make it so they don't travel too far.

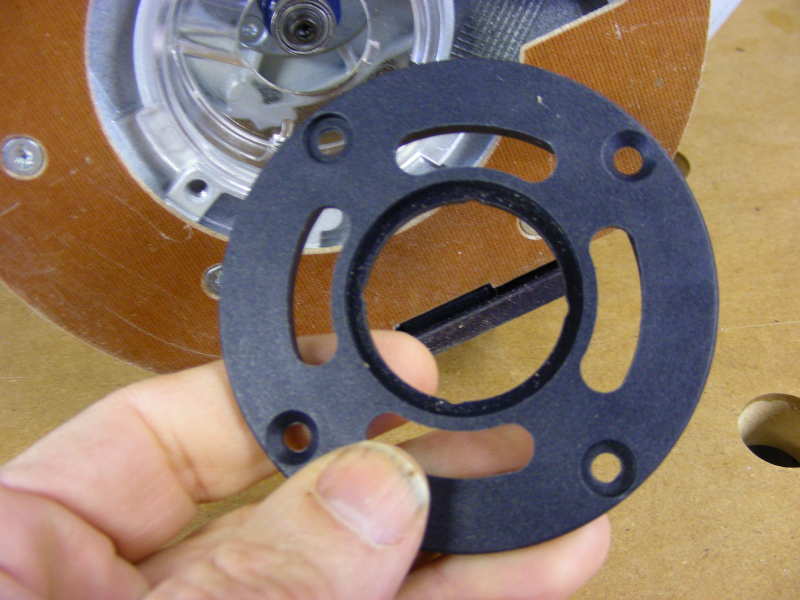

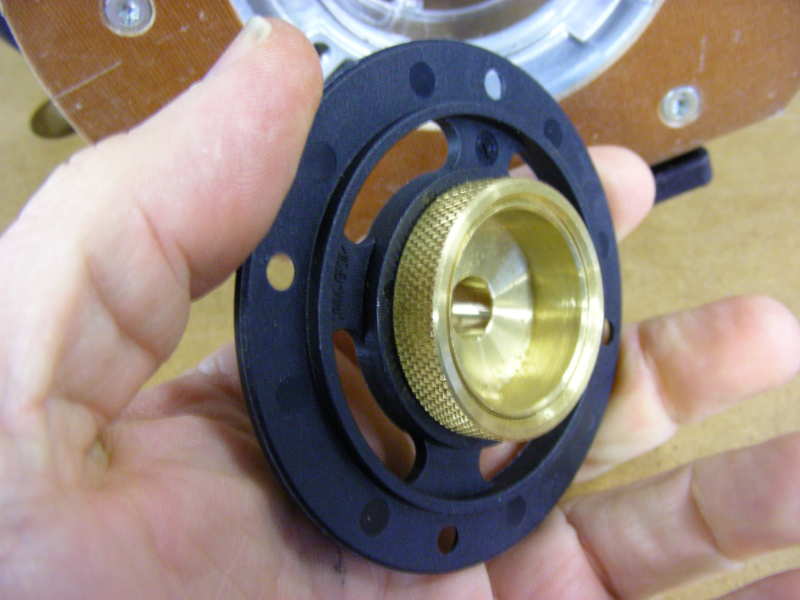

The

US version of the router comes supplied with a Guide Bushing adapter which fits

the standard Porter Cable bushing size (left). Festool supplies a metric

adapter with it's routers not sold in America and also offers it as an

accessory. While you could remove the bit and pull the top off that dust

shroud and install a bushing without removing the adapter ring, it is far easier

to just remove the two screws and install the bushing. The photo on the

right is a rear view of an installed bushing. We now have to mount it on

the router base.

The

US version of the router comes supplied with a Guide Bushing adapter which fits

the standard Porter Cable bushing size (left). Festool supplies a metric

adapter with it's routers not sold in America and also offers it as an

accessory. While you could remove the bit and pull the top off that dust

shroud and install a bushing without removing the adapter ring, it is far easier

to just remove the two screws and install the bushing. The photo on the

right is a rear view of an installed bushing. We now have to mount it on

the router base.

Here's that same bushing from the front (left) and then after it is installed on the router with the bit poking through (right).

There is no play at all either between the ring and the bushing or the ring and the base plate. By eye the bit looks centered and it should be repeatable.

Well, that's everything that came with the router. I did buy one accessory which is described below.

Accessories:

The Guide Stop does not come with a micro adjuster as with the OF 1400 so if you want the ability to easily dial in the position of your router with relation to the Guide Stop or Edge Guide you'll need to purchase this $20 item (left) It attaches to that threaded hole on the base that we talked about on page 1 of this review and one of the Guide Bars get's inserted into it and locked in place (right).

To operate the Micro Adjuster you loosen the thumbscrews on the router's base and twist the green knob on the micro adjuster. The dial is marked in 1/10mm (1/256") increments

OF 1010 in Use:

I had intended for this next section to include videos of the router in use but as [bad] luck would have it, when I was filming the OF1010 being used with a Leigh D4 dovetail jig I bumped into my cheapo tripod and the camera took a tumble and landed square on the steel mobile base of my table saw and broke. I never finished the review and even forgot about it until I received an email wondering if I was ever going to finish it.

I have used the OF1010 for through dovetails in 3/4" hardwood and blind dovetails in 1/2" hardwood using my Leigh and Woodhaven jigs. The router sits nicely on each jig and handles the larger stock with my Leigh 8mm bits while also working the half blind joints nicely with a 1/4" bearing bit. As can be expected with any router, even though with good dust extraction like the Festool, the dust flies all over being flung by the exposed bit. You won't want to do dovetails in a clients living room :)

Edge treatments and dados are a different matter as far as dust and the Festool does a pretty good job of collecting it. I like the Festool so much for edge treatment that I pretty much have gone to it exclusively for that task. It's comfortable and light to use and is small enough to steal most jobs from my Bosch Colt which now just sits in the drawer. I don't own any of Festool's 8mm bits so I do most of my edge treatment with 1/4" bits. I don't take as big a bite as I would with my larger routers but I prefer the more comfortable size and weight of the OF1010.

The OF1010 works well with the Festool guiderails and hole jig though I prefer to use the OF1400 and it's 1/2" bits for larger dados. I feel confident plowing through the work while attached to the guiderail if I'm using my 8mm straight bits but feel that the 1/4" bits vibrate too much.

I cant talk about the OF1010 without touching on the subject of bits. If you're happy using 1/4" bits then you can stop reading here but if you intend on using 8mm bits and haven't checked the prices you should do so before ordering the OF1010. Festool sells a wide assortment of 8mm shanked bits but I consider the prices above my reach as a hobbyist. Other than bit sets designed for the Leigh jigs, you will not find anything with 8mm shanks other than those sold by Festool so there aren't any lower priced alternatives. Honestly, I'm very happy with the router and was it not for the lack of 8mm bits the OF1010 would be my everyday go to router.

In Conclusion I really like the OF1010 for its super smooth operation, its comfortable size, weight and grip and it Festool quality construction. Every feature on this router works just like it's supposed to and it has adequate power for most jobs. I do wish there was a supply of more reasonably priced 8mm shank bitts but that is my only complaint. I would certainly buy this router again.