Page 2 of 2

Dust Be Gone

Overhead Blade Guard

and Dust Collector

by

Bill

Esposito

20 June 2005

Features, Construction and Quality:

The

Dust Be Gone frame is constructed from 1 3/4" and 1 1/2" square

steel tubing and is painted using a grey plastic powder coating. The workmanship

of both the welds and painting is outstanding. The

Dust Be Gone frame is constructed from 1 3/4" and 1 1/2" square

steel tubing and is painted using a grey plastic powder coating. The workmanship

of both the welds and painting is outstanding.

Click on the pictures on either side of this paragraph and look at the

quality. I've not seen much in the way of steel products which have looked

this good, definitely professional quality.

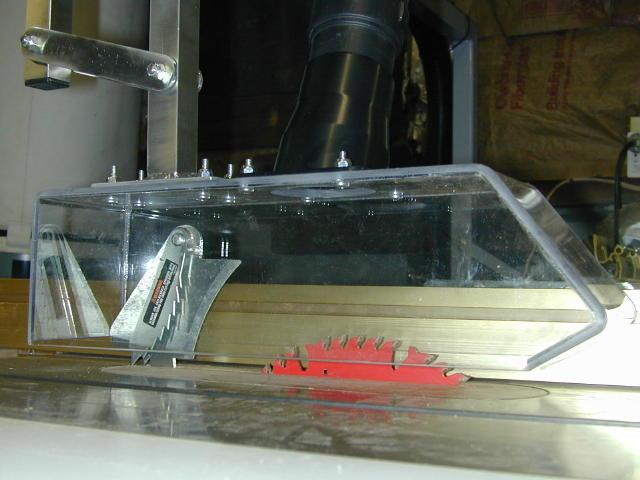

The

scissor assembly is 1 1/4" square aluminum tubing and the dust guard

is a clear polycarbonate. Like the steel the aluminum weld looks to be

of very good quality. The guard/dust hood is glued instead of in a frame

like many other guards. Unlike other guards the plastic has a lifetime

warranty. Also notice the nice hefty hose coupler, nothing is going to

break there. The

scissor assembly is 1 1/4" square aluminum tubing and the dust guard

is a clear polycarbonate. Like the steel the aluminum weld looks to be

of very good quality. The guard/dust hood is glued instead of in a frame

like many other guards. Unlike other guards the plastic has a lifetime

warranty. Also notice the nice hefty hose coupler, nothing is going to

break there.

Here is the advertised list of features of the Dust Be Gone:

Use:

Blade guards by their nature get in our way....tough, that's the

way it is. If you want to lower your risk of injury then a blade guard

is a good investment. This blade guard also provides the additional feature

of helping to reduce the amount of sawdust in your lungs and shop.

I figured I'd take this picture before I turned

on the saw so you could see what the guard looked like....clean. Notice

it is more than tall and long enough to work with my Biesemeyer splitter. I figured I'd take this picture before I turned

on the saw so you could see what the guard looked like....clean. Notice

it is more than tall and long enough to work with my Biesemeyer splitter.

In the photo at right you can see that with

my fence riding push block I rip about a 3/4" wide piece. Anything

smaller than that and you'll need to raise the guard and use a different

method. In the photo at right you can see that with

my fence riding push block I rip about a 3/4" wide piece. Anything

smaller than that and you'll need to raise the guard and use a different

method.

Speaking of another

method for ripping small pieces. I like to use the GRR-Ripper

for that however the Dust Be Gone guard is in the way. It is easy enough

to loosen the knob which holds the scissor assembly and remove it (left).

The hose just slips off and can be positioned out of the way and as you

see in the photo at right, there is plenty of room to use your favorite

jig. Speaking of another

method for ripping small pieces. I like to use the GRR-Ripper

for that however the Dust Be Gone guard is in the way. It is easy enough

to loosen the knob which holds the scissor assembly and remove it (left).

The hose just slips off and can be positioned out of the way and as you

see in the photo at right, there is plenty of room to use your favorite

jig.

The Dust Be Gone guard is designed to be locked down

over the work. This design assures maximum sawdust pickup as well as offering

protection from some forms of kick back. As shipped to me the scissor assembly

used two knobs to lock the guard into position. I felt there were a couple

of problems with this setup. First, the knobs were too small and my knuckles

would hit the frame. And second, positioning the guard required three hands,

one to hold the spring loaded guard in position and the other two to tighten

the knobs. The Dust Be Gone guard is designed to be locked down

over the work. This design assures maximum sawdust pickup as well as offering

protection from some forms of kick back. As shipped to me the scissor assembly

used two knobs to lock the guard into position. I felt there were a couple

of problems with this setup. First, the knobs were too small and my knuckles

would hit the frame. And second, positioning the guard required three hands,

one to hold the spring loaded guard in position and the other two to tighten

the knobs.  At my suggestion Steve from Segi

Inc. tried and liked the Rockler cam clamp. So did I. Now I can position

the guard with one hand and lock it in place with a simple flip of the

cam lever with the other. The lever can be mounted on either side at your

preference. I can't guarantee that the exact same Rockler clamp will ship

with future units but certainly some similar kind of cam lever clamp will. At my suggestion Steve from Segi

Inc. tried and liked the Rockler cam clamp. So did I. Now I can position

the guard with one hand and lock it in place with a simple flip of the

cam lever with the other. The lever can be mounted on either side at your

preference. I can't guarantee that the exact same Rockler clamp will ship

with future units but certainly some similar kind of cam lever clamp will.

In actual use the Dust Be Gone performed as advertised. In my dust collector

setup I have my Delta 50-850 collector wired for 220v and connected to

an X10 remote module.

For the top side collection with the Dust Be Gone, it was easier for me

to use one of my shop vacs (Fein) so I connected it to the hose and plugged

it into an X10 appliance

module, and addressed them the same. When I use the remote to turn

on the DC the vac connected to the Dust Be Gone also fires up. Of course

you can also hook the Dust Be Gone directly to your dust collection duct

work.

When I first tested the dust collection abilities I noticed that there

was actually more sawdust left on the table when using the Dust Be Gone

than not. At first I was perplexed and then I realized what was happening.

When not using the guard the sawdust from the blade shoots forward and

hits me in the belly but leaves the table pretty clean. With the Dust Be

Gone my shirt is clean and the small amount of sawdust left on the table

is just what escaped the guard, but didn't have enough velocity to travel

very far. All in all the Dust Be Gone sucks up the majority of sawdust

coming off the blade above the table.

I can also attest to the Dust Be Gone's ability to protect from kick back.

While I was testing the dust collection abilities by making cut after cut

in some MDF I got a little sloppy and you guessed it, bang! I had the blade

set to about half the gullet depth and it lifted the MDF, hit the guard

fairly violently and since I was using a GRR-Ripper as a push stick, I

was able to get control of the piece and turn off the saw.

The MDF hit the plastic guard with enough force that it raised it about

3/4 of an inch and even if I had not gotten it under control, it bought

me enough time to react and get out of the way.

Conclusion:

The Dust Be Gone worked as advertised and I think sucked up dust better

than I had expected. As a blade guard it served its purpose well and was

simple to remove when you had to perform an operation where it was in the

way. At present the Dust Be Gone has only one mounting option which is

the rear rail/table but as demand increases for other options, Segi Inc

will support them. We even devised an optional floor support during the

review process which will be available upon request.

It may not be as fancy colored as some guards out there but it is fully

functional, durable with high quality and workmanship at a reasonable price.

For info email Steve

at Segi Inc.

(502)494-2822

Price: $200 plus shipping

Other colors available, $15 plus 15 day lead time.

[Page 1] [Page 2]

[Home]

20 June 2005

Copyright © 2005 , Bill Esposito.

All Rights Reserved.

|