Page 1 of 3

Kreg Precision Miter Gauge

by

Bill Esposito

14 Aug 2004

Have you ever stood back to admire your work and had at that moment

notice that it is not really square? I have. Either my OEM Jet miter gauge

was off or my SCMS. It really didn't matter which, the end result was a

slightly out of square project. Enter the aftermarket miter gauges. There

are many "precision" miter gauges on the market and the latest

offering from Kreg is an update to an old standby, the FastTrak by Mark

Duginske.

As with all my reviews main intent is to try to provide the reader with

all the information they need to make an informed purchase. There will

be plenty of photo's, some very close up, which I hope will give you a

feel for the tool and which should preclude you from being surprised when

you open the box. Click on any picture to enlarge it. Many thanks to Brad

of Kreg Tool Company for providing

the gauge.

What's in the box?

The test unit was the Kreg Precision Miter Gauge w/24"

Add-On System. At left is a photo of the box contents. The gauge, already

assembled and calibrated is at far left. The two included flip stops are

at center and the 24" fence on the right. Everything was carefully

packaged and arrived without damage. Because Kreg is currently running

a special where you receive a second flip stop for free, it arrived in

a separate box. The test unit was the Kreg Precision Miter Gauge w/24"

Add-On System. At left is a photo of the box contents. The gauge, already

assembled and calibrated is at far left. The two included flip stops are

at center and the 24" fence on the right. Everything was carefully

packaged and arrived without damage. Because Kreg is currently running

a special where you receive a second flip stop for free, it arrived in

a separate box.

Assembly

The

first operation is dependent on your table saw slot and may not be required

for your set up. The gauge comes with the option of installing a T-Slot

washer for those miter tracks with a T-Slot. My Jet contractor's saw has

a T-Slot so I installed the washer which was simply screwing the washer

to the end of the bar. The bar is a healthy 24" long and by my measurement

23/32 wide by 3/8" thick and is made from aluminum. The

first operation is dependent on your table saw slot and may not be required

for your set up. The gauge comes with the option of installing a T-Slot

washer for those miter tracks with a T-Slot. My Jet contractor's saw has

a T-Slot so I installed the washer which was simply screwing the washer

to the end of the bar. The bar is a healthy 24" long and by my measurement

23/32 wide by 3/8" thick and is made from aluminum.

Before you do anything else now is as good a time as any to screw the long

black handle into the gauge

The next step is to adjust the slop out of the bar.

There are 5 nylon adjustment inserts

along the length of the bar (left). What we need to do is extend them out

from the bar just enough so that they take up the slack (right), but not

so far that they cause the bar to bind. There are 5 nylon adjustment inserts

along the length of the bar (left). What we need to do is extend them out

from the bar just enough so that they take up the slack (right), but not

so far that they cause the bar to bind.

The process is pretty easy. Simply insert the bar

in the slot until the first plug is in the slot. Wiggle the bar to feel

if there is any play, if there is you need to adjust the plug. We want

the plug to just "kiss" the edge of the slot...too tight and

the bar will bind. To adjust the plug use the supplied Allen wrench and

slowly screw in the set screw about 1/8th of a turn. Screwing in the set

screw pushes out the nylon plug. Push the bar into the slot again and wiggle

to feel the slop. If it is still loose pull the bar back until the plug

clears the slot and adjust it a little more. Once the first plug is adjusted

move on to the second one and repeat until all five are adjusted. If after

you finished the bar feels a little tight (mine did), just work it in the

slot a few times to wear down the nylon plugs. The process is pretty easy. Simply insert the bar

in the slot until the first plug is in the slot. Wiggle the bar to feel

if there is any play, if there is you need to adjust the plug. We want

the plug to just "kiss" the edge of the slot...too tight and

the bar will bind. To adjust the plug use the supplied Allen wrench and

slowly screw in the set screw about 1/8th of a turn. Screwing in the set

screw pushes out the nylon plug. Push the bar into the slot again and wiggle

to feel the slop. If it is still loose pull the bar back until the plug

clears the slot and adjust it a little more. Once the first plug is adjusted

move on to the second one and repeat until all five are adjusted. If after

you finished the bar feels a little tight (mine did), just work it in the

slot a few times to wear down the nylon plugs.

** UPDATE ** While the review was in progress Kreg made a modification

to the plugs. These changes and others are explained in the Product

Update section of this review.

The 24" Fence

In the three pictures above you can see the basic assembly of the fence.

Simply insert a pair of 1/4x20 hex head bolts into the side of the fence

with only one T-Slot (above left), extend them through the two inner holes

in the miter (center) and spin on the T-Knobs (right).

The other two holes are for the micro-adjust screws.

We will get into their use in a bit. The other two holes are for the micro-adjust screws.

We will get into their use in a bit.

The next step in the fence assembly is to stick the rule to the fence.

First, clean the top track where the rule will

be installed with alcohol to assure a good bond. Since the aluminum fence

will never be right up against the blade, start the tape at the 1"

mark (left) and then peal and stick the whole length of the fence (right). First, clean the top track where the rule will

be installed with alcohol to assure a good bond. Since the aluminum fence

will never be right up against the blade, start the tape at the 1"

mark (left) and then peal and stick the whole length of the fence (right).

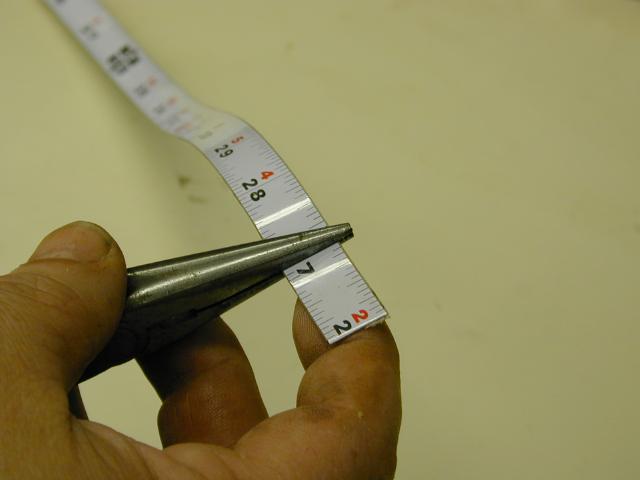

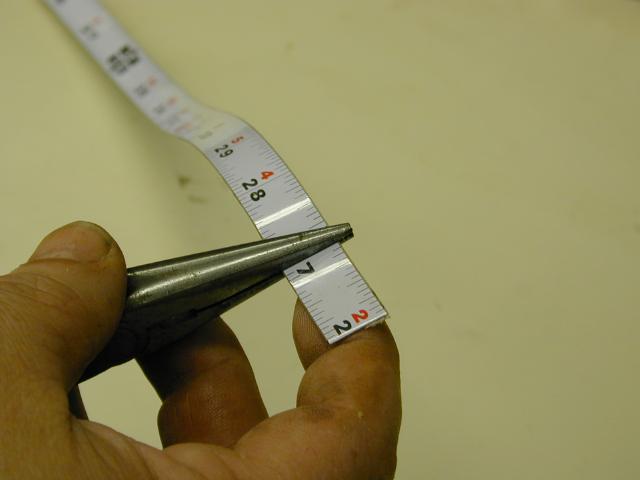

Tip - Pre-Cut the tape before

you install it

If you first install

the tape you'll have a bear of a time cutting it off since it

is metal. I dulled a couple of knives before I finally ended up

just grinding it off. Here's a tip Brad at Kreg told me about.

Just line up a

pair of long nose pliers on the mark where you want the rule to

break, bend it up tight against the pliers, and then bend it down

until it breaks off. The break is clean and much easier than trying

to cut the rule off once installed.

|

The fence also comes with a couple of nylon feet installed

to help it slide over your table. Kreg included two extra of these feet

in the bag with the allen wrenches as spare parts so don't lose them. The fence also comes with a couple of nylon feet installed

to help it slide over your table. Kreg included two extra of these feet

in the bag with the allen wrenches as spare parts so don't lose them.

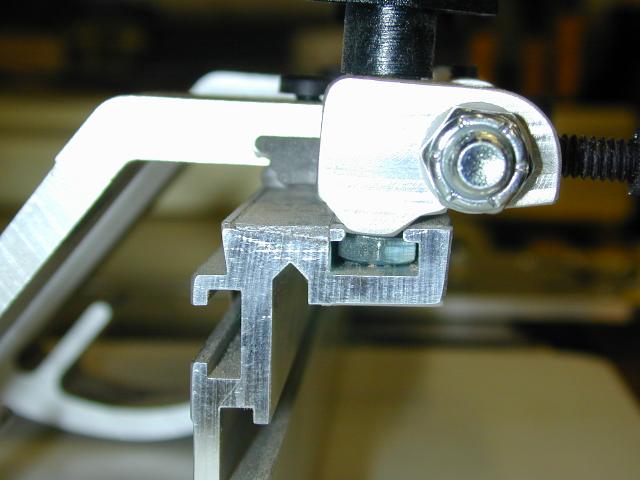

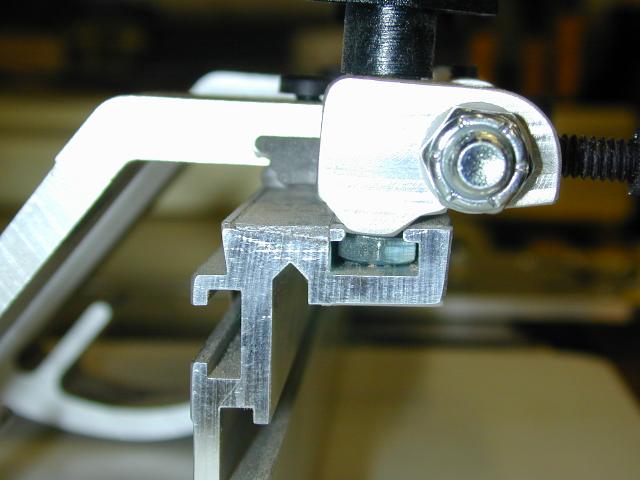

The last bit of assembly

we're going to do is assemble the flip stops. The photo at right shows

you the order of assembly (bolt not shown inserted through assembly for

clarity). Tighten the bolt just enough so that the stop swings freely but

is not loose. The nut on the end of the bolt is a self locking Nyloc. Don't

worry about the cursor position yet, we'll align everything when we align

the fence. The last bit of assembly

we're going to do is assemble the flip stops. The photo at right shows

you the order of assembly (bolt not shown inserted through assembly for

clarity). Tighten the bolt just enough so that the stop swings freely but

is not loose. The nut on the end of the bolt is a self locking Nyloc. Don't

worry about the cursor position yet, we'll align everything when we align

the fence.

Assemble both stops and install them in the T-Track on the top of the fence

(right).

[Page 1] [Page 2] [Page

3]

[Home]

14 Aug 2004

Copyright © 2004 , Bill Esposito.

All Rights Reserved.

|

The fence also comes with a couple of nylon feet installed

to help it slide over your table. Kreg included two extra of these feet

in the bag with the allen wrenches as spare parts so don't lose them.

The fence also comes with a couple of nylon feet installed

to help it slide over your table. Kreg included two extra of these feet

in the bag with the allen wrenches as spare parts so don't lose them.

The last bit of assembly

we're going to do is assemble the flip stops. The photo at right shows

you the order of assembly (bolt not shown inserted through assembly for

clarity). Tighten the bolt just enough so that the stop swings freely but

is not loose. The nut on the end of the bolt is a self locking Nyloc. Don't

worry about the cursor position yet, we'll align everything when we align

the fence.

The last bit of assembly

we're going to do is assemble the flip stops. The photo at right shows

you the order of assembly (bolt not shown inserted through assembly for

clarity). Tighten the bolt just enough so that the stop swings freely but

is not loose. The nut on the end of the bolt is a self locking Nyloc. Don't

worry about the cursor position yet, we'll align everything when we align

the fence.