Page 3 of 3

Kreg Precision Miter Gauge

by

Bill Esposito

14 Aug 2004

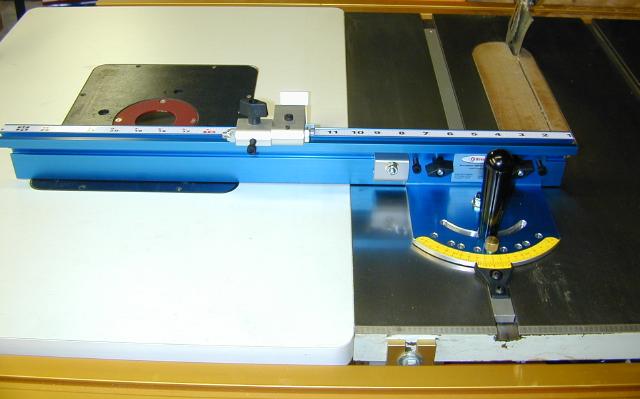

Product Updates

For various reasons this

review took place over the course of 4 months. During that time I was in

contact with Kreg discussing some issues I found while reviewing the gauge.

Either in response to my inquiries or because of the normal transition

of a new product into production, or both, a number of changes were made

to improve the product. In these pictures you see the most noticeable change...Kreg

blue anodizing. For various reasons this

review took place over the course of 4 months. During that time I was in

contact with Kreg discussing some issues I found while reviewing the gauge.

Either in response to my inquiries or because of the normal transition

of a new product into production, or both, a number of changes were made

to improve the product. In these pictures you see the most noticeable change...Kreg

blue anodizing.

|