Trion PS/PSB 300 EQ

Jigsaws

by

FESTOOL

by

Bill Esposito

1 November 2003

While my 30 year old Craftsman jigsaw isn't the most used tool in my

woodshop now it has received quite a workout over the years as a home

improvement/repair tool. When I took up woodworking as a hobby a few

years ago, splintering and blade wandering caused both by the saw's

design and the use of cheap blades relegated the saw to its storage

drawer for all but the most rough cutting needs.

One of the newest jigsaws to hit the US market is the Trion by FESTOOL. The

Trion is available in both D-handle and barrel grip styles and thanks

to Bob Marino of FESTOOL I was

able to evaluate both versions.

Like always my main intent is to try to provide the reader with all the

information they need to make an informed purchase. There will be

plenty of photo's, some very close up, which I hope will give you a

feel for the tool. Click on any picture to enlarge it.

What's in the box?

Let's begin with the barrel grip version.

Each saw comes packed in a case which FESTOOL calls a Systainer.

The contents include the saw, a dust port adapter, removable power

cord, chip guard, splinter guard, instruction manual and warranty cards

and a pair of blades. Let's begin with the barrel grip version.

Each saw comes packed in a case which FESTOOL calls a Systainer.

The contents include the saw, a dust port adapter, removable power

cord, chip guard, splinter guard, instruction manual and warranty cards

and a pair of blades.

Not just any old case!

The Systainer is a high impact

plastic case designed not only to hold the tool, but also to be

stackable with other Systainers as well as on FESTOOL's line of vacuum

cleaners. At right you can see two Systainers stacked and secured

together. You will notice that the latches normally used to latch the

lid have been repositioned to latch the Systainer above. Repositioning

is accomplished by simply sliding the latch up and then snapping it to

latch the Systainer. The Systainer is a high impact

plastic case designed not only to hold the tool, but also to be

stackable with other Systainers as well as on FESTOOL's line of vacuum

cleaners. At right you can see two Systainers stacked and secured

together. You will notice that the latches normally used to latch the

lid have been repositioned to latch the Systainer above. Repositioning

is accomplished by simply sliding the latch up and then snapping it to

latch the Systainer.

A closer look at the Saws and their Features:

Here's the specs on the Trion saws PS 300 EQ/PSB 300 EQ. Of note are

the 6 amp power, Pendulum (orbital) action, and 5 pound weight:

- Power Consumption 720 W/6 A 120 v AC

- Stroke rate - 1" (2.54 cm) 1000-2900 spm

- Pendulum stroke adjustment 4 stages

- Bevel adjustment 0-45°

- Cutting depth wood 4 3/4" (120.65 mm)

- Cutting depth non-ferrous metal 3/4" (20 mm)

- Cutting depth soft steel 3/8" (10 mm)

- Weight 5.06 lbs/ 5.29 lbs (2.3 kg/2.4 kg)

The list of features is long so let's get to it.

Power, motor and speed control:

The motor is a

strong 6 amps which is on par with the other new jigsaws on the market.

The Trion features electronic speed control or what FESTOOL refers to

as Multi-Material-Control electronics. What this means is that the saw

will adjust for changing loads and keep the cutting speed constant.

This is actually a necessary feature since neither model of the Trion

feature trigger controlled speed (photo's left and right). The motor is a

strong 6 amps which is on par with the other new jigsaws on the market.

The Trion features electronic speed control or what FESTOOL refers to

as Multi-Material-Control electronics. What this means is that the saw

will adjust for changing loads and keep the cutting speed constant.

This is actually a necessary feature since neither model of the Trion

feature trigger controlled speed (photo's left and right).

If you are paying

attention you noticed that there isn't a power cord in the above

pictures. The Trion's power cord is detachable via twist lock. This is

a great feature for storage and greatly improves the ease of handling

of the generous 13 foot, extremely flexible power cord. If you are paying

attention you noticed that there isn't a power cord in the above

pictures. The Trion's power cord is detachable via twist lock. This is

a great feature for storage and greatly improves the ease of handling

of the generous 13 foot, extremely flexible power cord.

The barrel grip

Trion has a slide switch (right) which applies power. For me it was a

bit awkward to adjust the speed while gripping the saw. The D-handle

(seen behind the barrel grip at right) does have a trigger and a

trigger lock but the trigger is not variable speed. The speed is still

selected by the thumbwheel. The barrel grip

Trion has a slide switch (right) which applies power. For me it was a

bit awkward to adjust the speed while gripping the saw. The D-handle

(seen behind the barrel grip at right) does have a trigger and a

trigger lock but the trigger is not variable speed. The speed is still

selected by the thumbwheel.

Pendulum action:

The pendulum or

orbital action is engaged by moving the lever (left) near the blade

mechanism. There are three different levels of action (1,2,3) plus off

(0). The difference in speed and ease of cutting, especially in thick

hardwood is amazing. Using one of FESTOOL's exclusive FSG blades, which are thicker

than the normal blade, and the pendulum action and you can cut through

4" posts like they were butter. The blade application chart suggests

that for some blade/cutting applications it's better to turn off

pendulum to achieve the splinter free cut. My tests confirmed that as

well. The pendulum or

orbital action is engaged by moving the lever (left) near the blade

mechanism. There are three different levels of action (1,2,3) plus off

(0). The difference in speed and ease of cutting, especially in thick

hardwood is amazing. Using one of FESTOOL's exclusive FSG blades, which are thicker

than the normal blade, and the pendulum action and you can cut through

4" posts like they were butter. The blade application chart suggests

that for some blade/cutting applications it's better to turn off

pendulum to achieve the splinter free cut. My tests confirmed that as

well.

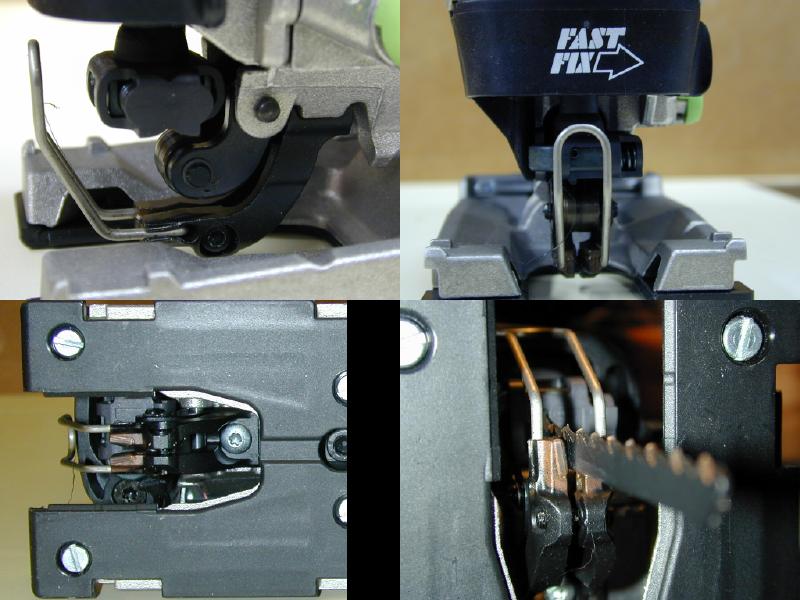

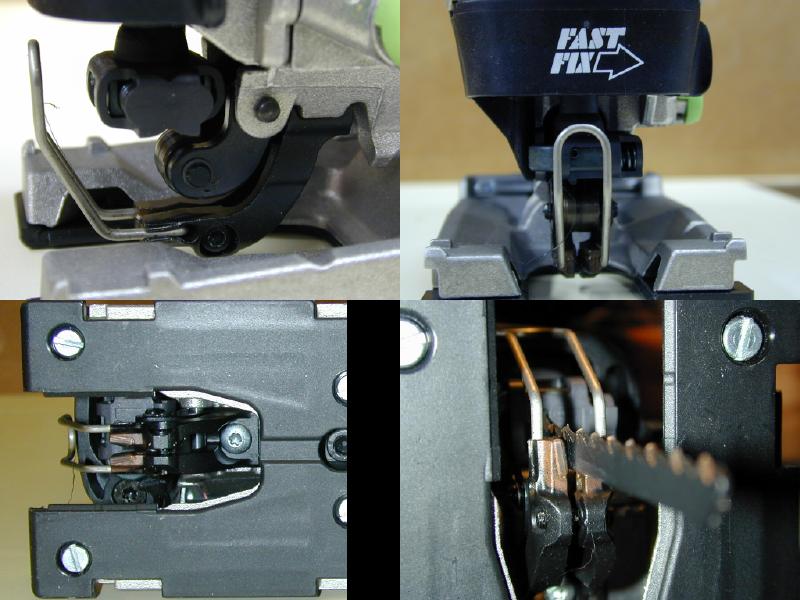

Blade Change Mechanism:

Changing blades

on the Trion is a snap. At right you can see the only motion required

and that is to lift a spring loaded lever . Changing blades

on the Trion is a snap. At right you can see the only motion required

and that is to lift a spring loaded lever .

It is literally as easy as lifting the lever and inserting the blade

and letting go of the lever to lock the blade into place.

Click here to see a short video of a

blade

change. Click here to see a short video of a

blade

change.

Blade Guide:

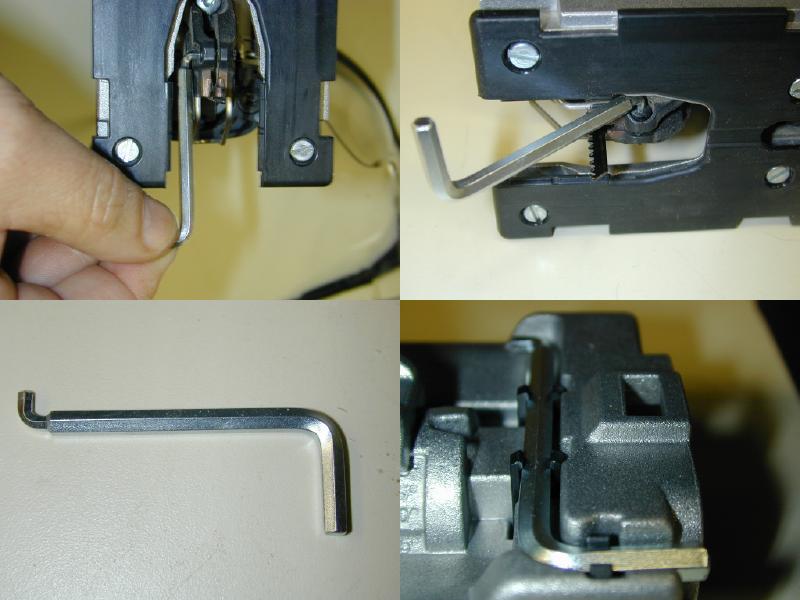

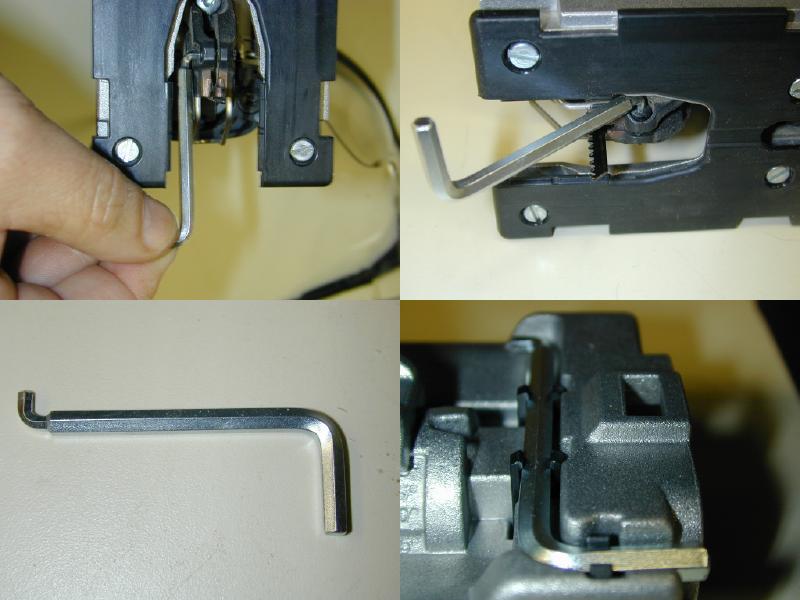

The next

innovative feature is the blade guide system. Much like a band saw the

Trion captures the blade between a pair of carbide guides. The collage

of pictures at left show (clockwise from upper left) the guide and

adjustment hex screw, the guide front on, the guide from below, and the

guide adjusted for the blade. The photo at right shows the included

allen wrench being used to adjust the guide. The wrench conveniently

stows right in the base plate of the saw. The next

innovative feature is the blade guide system. Much like a band saw the

Trion captures the blade between a pair of carbide guides. The collage

of pictures at left show (clockwise from upper left) the guide and

adjustment hex screw, the guide front on, the guide from below, and the

guide adjusted for the blade. The photo at right shows the included

allen wrench being used to adjust the guide. The wrench conveniently

stows right in the base plate of the saw.

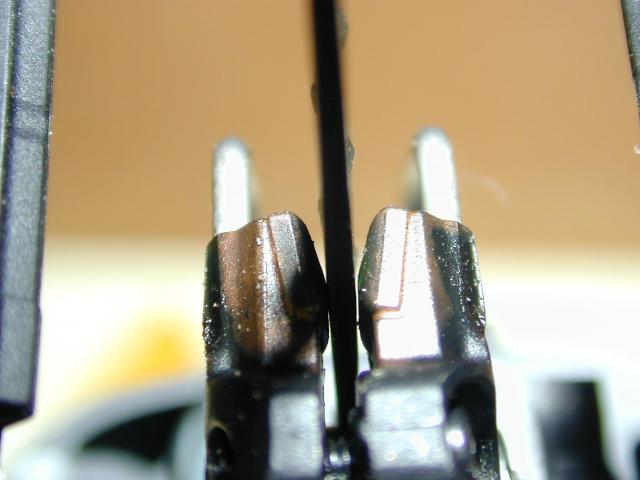

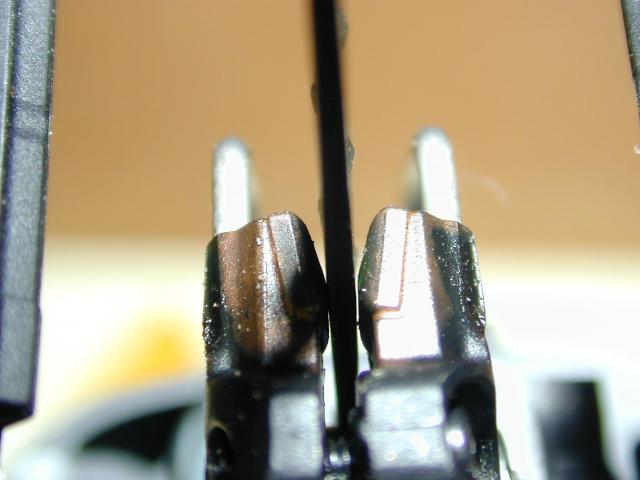

The manual instructs you to

adjust the guide until it "almost touches" the blade and that the blade

must move freely. In the photo at left I adjusted it to where I thought

it should be. The blade did move freely and because you actually draw

the right guide to the blade while the left guide stays almost

stationary, I thought this was correct. Well it is correct if you leave

pendulum mode off but in this case, I cut about 6" of wood with the

pendulum mode on 3. The result can be seen in the photo of the

overheated blade at right. When I noticed this the blade would no

longer move freely. Apparently the pendulum mode requires more

clearance than "almost". In my subsequent tests I adjusted the guide

with more clearance for times when I used the pendulum mode and did not

have another problem. I did however have the guide adjusted for a fine

cutter blade and forgot to re-adjust it for the thicker blade and had

the same overheating happen. The manual instructs you to

adjust the guide until it "almost touches" the blade and that the blade

must move freely. In the photo at left I adjusted it to where I thought

it should be. The blade did move freely and because you actually draw

the right guide to the blade while the left guide stays almost

stationary, I thought this was correct. Well it is correct if you leave

pendulum mode off but in this case, I cut about 6" of wood with the

pendulum mode on 3. The result can be seen in the photo of the

overheated blade at right. When I noticed this the blade would no

longer move freely. Apparently the pendulum mode requires more

clearance than "almost". In my subsequent tests I adjusted the guide

with more clearance for times when I used the pendulum mode and did not

have another problem. I did however have the guide adjusted for a fine

cutter blade and forgot to re-adjust it for the thicker blade and had

the same overheating happen.

My recommendation is that unless you need the guide for a specific cut,

adjust it to give the blades plenty of clearance so you don't overheat

and ruin a blade. The fine and scroll blades seem to benefit the most

from the guide.

Base Runner:

The base runner is constructed

from what appears to be cast aluminum and has a plastic skid plate

attached to its bottom. The runner is an integral part of the Trion's

dust extraction system. I'm not sure of the purpose of the rear ducts

on the runner in the photo at left. The base runner is constructed

from what appears to be cast aluminum and has a plastic skid plate

attached to its bottom. The runner is an integral part of the Trion's

dust extraction system. I'm not sure of the purpose of the rear ducts

on the runner in the photo at left.

As well as housing the dust

ports and the allen wrench, the base runner also has 0°, 15°,

30° and 45° angle indexes although only 0° has a positive

stop. It is difficult to see in the photo at right but even though the

base is cast, the angle index lines up perfectly. To adjust the angle,

loosen the screw with the large end of the allen wrench and push the

base runner forward about 1/4". That will move it out of its 0°

indexing position and allow you to change the angle. Set the angle and

tighten the locking screw. The chip guard cannot be used when the saw

is at anything other than 0° so it must be removed before you

adjust the angle. As well as housing the dust

ports and the allen wrench, the base runner also has 0°, 15°,

30° and 45° angle indexes although only 0° has a positive

stop. It is difficult to see in the photo at right but even though the

base is cast, the angle index lines up perfectly. To adjust the angle,

loosen the screw with the large end of the allen wrench and push the

base runner forward about 1/4". That will move it out of its 0°

indexing position and allow you to change the angle. Set the angle and

tighten the locking screw. The chip guard cannot be used when the saw

is at anything other than 0° so it must be removed before you

adjust the angle.

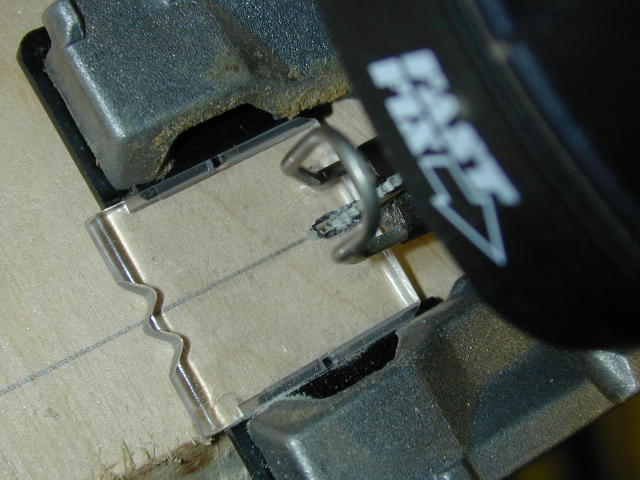

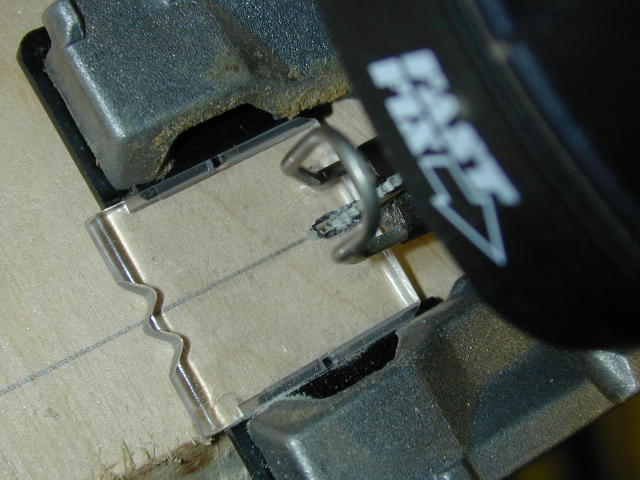

The base runner

can be adjusted either forward or back from its default position. With

the runner in the front position (left) you can even make pilot-less

plunge cuts. More on that later. The instructions refer to the runner

in the front position meaning that the locking screw is towards the

front of the adjustment slot. In reality the runner is to the rear and

the blade is to the front. The clear plastic piece around the blade is

the chip guard. The base runner

can be adjusted either forward or back from its default position. With

the runner in the front position (left) you can even make pilot-less

plunge cuts. More on that later. The instructions refer to the runner

in the front position meaning that the locking screw is towards the

front of the adjustment slot. In reality the runner is to the rear and

the blade is to the front. The clear plastic piece around the blade is

the chip guard.

Dust Extraction:

You can't say

FESTOOL without thinking about their line of quiet vacuums. All of

FESTOOL's tools are designed to integrate with their vacs. As mentioned

earlier the dust extractor adapter plugs into the base runner. For best

efficiency you should also install the chip guard. You can't say

FESTOOL without thinking about their line of quiet vacuums. All of

FESTOOL's tools are designed to integrate with their vacs. As mentioned

earlier the dust extractor adapter plugs into the base runner. For best

efficiency you should also install the chip guard.

I did try the dust extraction and it worked pretty well but my Shop

Vac© is so noisy that I stopped using it. If you want to keep your

sanity (and hearing) while using a shop vacuum cleaner to catch dust

from portable saws and sanders, I suggest you look at the quieter

vaccums on the market. Of course Festool has a variety of vacs which

should work great.

Chip and Splinter Guards:

At

left is the chip guard and at right is the splinter guard. The chip

guard is used to aid the dust collection effort and the splinter guard

will enable you to make fine, finish cuts (with the right blade) The

use of these guards does obscure your sight of the cut line especially

after they get dusty. At

left is the chip guard and at right is the splinter guard. The chip

guard is used to aid the dust collection effort and the splinter guard

will enable you to make fine, finish cuts (with the right blade) The

use of these guards does obscure your sight of the cut line especially

after they get dusty.

TIP

Here's two tips which will help you keep

a bead on that cut line.

First Tip:

Wipe both the Chip and Splinter Guards with a fabric softener sheet.

This will help keep dust from sticking to them. Re-apply as necessary.

Second Tip: (24 Nov 2006) OK, so

I'm getting old, my eyesight stinks and

the Trion is kind of tough to see the blade with the guard on.

Here's what I've been doing as of late which works well.

I install the splinter guard all the way. Then I remove it and touch

the edges of the cut with a Sharpie(tm) marker.

Now here's the actual tip. When I reinstall the splitter guard, I

only push it on so it just extends past the teeth of the blade. This

is enough to perform its function and the kerf in the plastic is

then used as a guide.

Even with the blade running and becoming invisible I've been able to

use the kerf as the guide....much more accurate than trying to use

the point at the end of the splinter guard. This picture was posed

which is why the point doesn't line up with the line, but you get

the idea, the kerf is readily visible.

Click to enlarge

Click to enlarge

|

Different Strokes for Different Folks:

Alright, I know, that's an corny old cliche but I needed a lead in for

this next section. As I mentioned above, the Trion comes in two styles.

The conventional D-handle and the barrel grip. I'm going to be honest

and tell you that I still don't know which one I prefer since each has

its own merits. Below is a set of photos of the two styles:

What I like about

the D-handle is the sure grip. It is the style that I've used all my

life and it is the most comfortable for me. It is certainly better

suited for home improvement work where you might be using it in awkward

positions. For fine work however the higher grip can cause some

stability and control issues. What I like about

the D-handle is the sure grip. It is the style that I've used all my

life and it is the most comfortable for me. It is certainly better

suited for home improvement work where you might be using it in awkward

positions. For fine work however the higher grip can cause some

stability and control issues.

For accuracy in following a

line I prefer the barrel grip version. It's lower center of gravity

makes it easier to follow the line and easier to keep the saw planted

flat on the work. I find the grip is unsure when I'm carrying it but

once it is on the work it feels secure. I prefer having the crotch of

my thumb-forefinger up against the front of the saw (left) This seems

to give me the best control and the surest grip. If need be you can

grab the top knob with your other hand to stabilize the saw. For accuracy in following a

line I prefer the barrel grip version. It's lower center of gravity

makes it easier to follow the line and easier to keep the saw planted

flat on the work. I find the grip is unsure when I'm carrying it but

once it is on the work it feels secure. I prefer having the crotch of

my thumb-forefinger up against the front of the saw (left) This seems

to give me the best control and the surest grip. If need be you can

grab the top knob with your other hand to stabilize the saw.

If I had my druthers I'd have one of each style.

Warranty:

This caused me a little confusion because the owners manual states that

the Trion comes with a 1 year warranty. In reality the Trion comes with

a 3 year warranty. Included with the documentation is a warranty card

which entitles the owner to a 1+2 year warranty....that's 3 years.

The Trion is warranted for defects in materials and workmanship for a

period of 3 years and there is no exclusion for commercial use. If a

problem occurs within the first year, Festool will pay for shipping

BOTH ways. If the problem occurs during year 2 or 3, Festool will pay

for return shipping to you only. I don't think I've ever seen any

product where the manufacturer payed for shipping both ways.

Oh yea, if you are disappointed it will probably be because you bought

the barrel grip and don't like the feel or bought the D-handle and

subsequently decided you wanted a barrel grip. Not to worry, the Trion

comes with a 30 day money back guarantee. You can either return it for

a refund or swap it for a different grip style within the first 30 days.

Performance:

I've put both saws through a variety of tests and they do both work

well. I used Festool blades for these tests and the blades are

substantially responsible for the quality of the cut. The Trion can

also use Bosch blades and I've put a cross reference column in the blade chart I made. I tried to

get some good photos of the cuts but was unable to get the quality of

photos I had hoped for.

Effect of blade Guide on accuracy of cut:

The results of

these tests were mixed. With some wood thickness/blade types the

results were excellent while with others they were disappointing. The

blade guide did perform very well with wood which was less than 1"

thick and excellent with 3/4" plywood as I expected it to. It also

performed well with the thicker wood if I used the heavier duty blades

like the S 75-4 FS (left). The results of

these tests were mixed. With some wood thickness/blade types the

results were excellent while with others they were disappointing. The

blade guide did perform very well with wood which was less than 1"

thick and excellent with 3/4" plywood as I expected it to. It also

performed well with the thicker wood if I used the heavier duty blades

like the S 75-4 FS (left).

It did not

perform as well with the thicker wood when I used the finish blades

like the S 75/2,5 (right). The disappointment here is that the fine

tooth blades do make a great, almost ready to finish cut but since they

are thin they were not accurate in the thicker wood during my tests. In

order to get the accuracy I had to use the S 75/4 FS blade. This blade

while good is not give the finish quality of the fine toothed blade and

therefore the cut will require more prep work before the surface is

ready to finish. Is it really a big deal in the scheme of things? No,

but it does not live up to Festool's unqualified claim of "No

refinishing work". It did not

perform as well with the thicker wood when I used the finish blades

like the S 75/2,5 (right). The disappointment here is that the fine

tooth blades do make a great, almost ready to finish cut but since they

are thin they were not accurate in the thicker wood during my tests. In

order to get the accuracy I had to use the S 75/4 FS blade. This blade

while good is not give the finish quality of the fine toothed blade and

therefore the cut will require more prep work before the surface is

ready to finish. Is it really a big deal in the scheme of things? No,

but it does not live up to Festool's unqualified claim of "No

refinishing work".

Tilting the saw to 30 degrees,

setting the pendulum to 1 and utilizing the S 75/4 FS blade in the same

2" thick white oak the results were impressive. If you look closely at

the photo on the left you can see that there is a very slight bowing at

the bottom of the cut although in reality, it is nothing that a little

sanding wont fix (right). I would consider the accuracy of this angled

cut in some very hard wood to be very good. Tilting the saw to 30 degrees,

setting the pendulum to 1 and utilizing the S 75/4 FS blade in the same

2" thick white oak the results were impressive. If you look closely at

the photo on the left you can see that there is a very slight bowing at

the bottom of the cut although in reality, it is nothing that a little

sanding wont fix (right). I would consider the accuracy of this angled

cut in some very hard wood to be very good.

Quality of Cut:

Now If you want

to see a flawless cut take a look at the photo at left. I used the same

fine cut blade, S 75/2,5, as above with excellent results. The

combination of the blade guide, splinter guard and fine toothed blade

produced a ready to finish result in this 3/4" birch plywood. You can't

tell from the photo but that cut is burnished similar to the way a good

10" table saw blade such as the Freud LU85 would. Now If you want

to see a flawless cut take a look at the photo at left. I used the same

fine cut blade, S 75/2,5, as above with excellent results. The

combination of the blade guide, splinter guard and fine toothed blade

produced a ready to finish result in this 3/4" birch plywood. You can't

tell from the photo but that cut is burnished similar to the way a good

10" table saw blade such as the Freud LU85 would.

At right is some scroll work performed with the S 50/1,4 K blade on a

piece of 3/4 cherry. I did not use the splinter guard. The angle of the

cut was accurate and what I hope you can see is the smoothness of the

cut as indicated by the gloss of the wood.

I did learn that the Trion has

variable speed for a reason. At left (top) you can see a scroll cut I

made with the speed on high...burned the wood pretty good. I slowed the

blade speed down to "3" and the results were much better. Here's where

the dial type speed control has the advantage over the trigger. With

the dial once you have found the correct speed and set it, it's stays

at that speed until you select another. If you have a variable speed

trigger you would be hard pressed to keep it the same speed through the

entire cut, let alone the next cut. I did learn that the Trion has

variable speed for a reason. At left (top) you can see a scroll cut I

made with the speed on high...burned the wood pretty good. I slowed the

blade speed down to "3" and the results were much better. Here's where

the dial type speed control has the advantage over the trigger. With

the dial once you have found the correct speed and set it, it's stays

at that speed until you select another. If you have a variable speed

trigger you would be hard pressed to keep it the same speed through the

entire cut, let alone the next cut.

Following a line:

I found that the Trion was very easy to keep to the line

and didn't tend to wander at all. There are a couple of gotchas though.

If you use the splinter guard you will have a hard time following a

curve because you can't use the pointer on the guard...it's a half inch

ahead of the blade. You actually have to use the blade to follow the

line for the most accurate cut. With the guard as it builds up with

dust seeing the line is a problem.

I also discovered that the point on the splinter guard did not always

line up with the blade. I'm not sure why although I believe it is

because the blade is not always exactly centered in the runner opening.

I could loosen the runner locking screw and make the alignment more

accurate. In any case it was sometimes about the thickness of the line

off to one side or the other. Once you know this it's easy to align the

pointer in relation to the line to get adequate accuracy but for

exacting cuts, you should use the blade as the guide..

Plunge Cutting:

This method

intrigued me. I was curious how a jigsaw could plunge cut without a

pilot hole and not bounce all over the place. The secret is in the

pendulum action. Simply set the pendulum to 3 and move the shoe all the

way back so that the blade is as close to the front of the shoe as it

can go. Then resting on the front of the shoe, slowly tilt the saw into

the wood. Once you have it through like the vertical cut at right, you

can then use the saw normally to finish the cut. In this case I have to

cut downward toward the horizontal cut and then turn the saw around and

cut up to the other side of the opening. The results were rather good

as you can see in the photo at right where I was cutting out a drawer

opening in some luan plywood. These cuts was made with the S 75/2,5

fine toothed blade. This method

intrigued me. I was curious how a jigsaw could plunge cut without a

pilot hole and not bounce all over the place. The secret is in the

pendulum action. Simply set the pendulum to 3 and move the shoe all the

way back so that the blade is as close to the front of the shoe as it

can go. Then resting on the front of the shoe, slowly tilt the saw into

the wood. Once you have it through like the vertical cut at right, you

can then use the saw normally to finish the cut. In this case I have to

cut downward toward the horizontal cut and then turn the saw around and

cut up to the other side of the opening. The results were rather good

as you can see in the photo at right where I was cutting out a drawer

opening in some luan plywood. These cuts was made with the S 75/2,5

fine toothed blade.

Power and speed control:

Here's another area where the Trion really shines. My last test was to

use the S 105/4 FSG Festool unique blade which is rated to cut wood up

to 4 3/4" thick. This blade is extra long and thick. I wanted to see

how the power and electronic speed control handled the arduous task of

cutting some 4 1/2" thick maple. I setup the saw for a pendulum of 3

and a speed of 6. The piece of wood was a chunk of 8" wide 4 1/2" thick

maple which had only been air dried for about a year. While making the

cut I at times let the saw do all the work and at other times

forcefully pushed the saw into the work in an effort to change the load

on the motor and see how the speed control reacted. I did not attach

the vacuum because I wanted to be able to hear the saw's motor.

I captured this test in a 25 second mpeg clip. It's about 6 mebabytes

in size so it may take a bit of time to get started. What I want you to

do is listen to the saw....the motor pitch stays pretty constant

throughout the clip even when you can visually see me forcing the saw.

I was very impressed with both the power and speed control of the

Trion. I also think the speed of the cut was exceptional for a jigsaw. I captured this test in a 25 second mpeg clip. It's about 6 mebabytes

in size so it may take a bit of time to get started. What I want you to

do is listen to the saw....the motor pitch stays pretty constant

throughout the clip even when you can visually see me forcing the saw.

I was very impressed with both the power and speed control of the

Trion. I also think the speed of the cut was exceptional for a jigsaw.

movie

clip of test cut

Conclusion:

The Trion is a great saw. It has exceptional power, handles great, has

very good dust collection, can be combined with the correct blade to

provide almost ready to finish cuts as well as accurate cuts and it

comes with a superior case. The blade change mechanism is extremely

simple to use and secures the blade solid as a rock. The three year

warranty is exceptional as well. For me, the Trion elevates the jigsaw

to a finish tool.

The biggest drawback of the Trion to some will be it's cost. At a

retail of $250 it will be out of the reach of some woodworkers. The

case while very well made is also overkill for many woodworkers who

will just pile it on top of the other cases for their portable power

tools. Perhaps Festool could offer a version without a case and save

the purchaser $10. On the up side Festool does run periodic specials

and the Trion has been sold for as little as $195 which is not much

more than the Metabo or new Makita. Lastly, you have to understand that

you will not be able to get ready to finish cuts in every case. The

quality and accuracy of the cut is material and blade dependent but

even at worst case the accuracy should surpass that of an unsupported

(no guide) blade.

Should you buy the Trion? All I will say is that if you do buy it you

wont be disappointed.

[Home]

Copyright © 2003 , Bill Esposito

All Rights Reserved.

|

The motor is a

strong 6 amps which is on par with the other new jigsaws on the market.

The Trion features electronic speed control or what FESTOOL refers to

as Multi-Material-Control electronics. What this means is that the saw

will adjust for changing loads and keep the cutting speed constant.

This is actually a necessary feature since neither model of the Trion

feature trigger controlled speed (photo's left and right).

The motor is a

strong 6 amps which is on par with the other new jigsaws on the market.

The Trion features electronic speed control or what FESTOOL refers to

as Multi-Material-Control electronics. What this means is that the saw

will adjust for changing loads and keep the cutting speed constant.

This is actually a necessary feature since neither model of the Trion

feature trigger controlled speed (photo's left and right). If you are paying

attention you noticed that there isn't a power cord in the above

pictures. The Trion's power cord is detachable via twist lock. This is

a great feature for storage and greatly improves the ease of handling

of the generous 13 foot, extremely flexible power cord.

If you are paying

attention you noticed that there isn't a power cord in the above

pictures. The Trion's power cord is detachable via twist lock. This is

a great feature for storage and greatly improves the ease of handling

of the generous 13 foot, extremely flexible power cord. The barrel grip

Trion has a slide switch (right) which applies power. For me it was a

bit awkward to adjust the speed while gripping the saw. The D-handle

(seen behind the barrel grip at right) does have a trigger and a

trigger lock but the trigger is not variable speed. The speed is still

selected by the thumbwheel.

The barrel grip

Trion has a slide switch (right) which applies power. For me it was a

bit awkward to adjust the speed while gripping the saw. The D-handle

(seen behind the barrel grip at right) does have a trigger and a

trigger lock but the trigger is not variable speed. The speed is still

selected by the thumbwheel. The pendulum or

orbital action is engaged by moving the lever (left) near the blade

mechanism. There are three different levels of action (1,2,3) plus off

(0). The difference in speed and ease of cutting, especially in thick

hardwood is amazing. Using one of FESTOOL's exclusive FSG blades, which are thicker

than the normal blade, and the pendulum action and you can cut through

4" posts like they were butter. The blade application chart suggests

that for some blade/cutting applications it's better to turn off

pendulum to achieve the splinter free cut. My tests confirmed that as

well.

The pendulum or

orbital action is engaged by moving the lever (left) near the blade

mechanism. There are three different levels of action (1,2,3) plus off

(0). The difference in speed and ease of cutting, especially in thick

hardwood is amazing. Using one of FESTOOL's exclusive FSG blades, which are thicker

than the normal blade, and the pendulum action and you can cut through

4" posts like they were butter. The blade application chart suggests

that for some blade/cutting applications it's better to turn off

pendulum to achieve the splinter free cut. My tests confirmed that as

well. Changing blades

on the Trion is a snap. At right you can see the only motion required

and that is to lift a spring loaded lever .

Changing blades

on the Trion is a snap. At right you can see the only motion required

and that is to lift a spring loaded lever .

Tilting the saw to 30 degrees,

setting the pendulum to 1 and utilizing the S 75/4 FS blade in the same

2" thick white oak the results were impressive. If you look closely at

the photo on the left you can see that there is a very slight bowing at

the bottom of the cut although in reality, it is nothing that a little

sanding wont fix (right). I would consider the accuracy of this angled

cut in some very hard wood to be very good.

Tilting the saw to 30 degrees,

setting the pendulum to 1 and utilizing the S 75/4 FS blade in the same

2" thick white oak the results were impressive. If you look closely at

the photo on the left you can see that there is a very slight bowing at

the bottom of the cut although in reality, it is nothing that a little

sanding wont fix (right). I would consider the accuracy of this angled

cut in some very hard wood to be very good.