Admittedly, before being asked to review this fence I had looked

at the TS-III often but never seriously considered it. Even though every Incra owner

with whom I had communicated loved it, my thoughts were that the fence was too precise

and too gimmicky for the average hobbyist...like myself. Well my impression

has certainly changed since the TS-III was installed on my saw. I don't think

my old after-market fence will be re-installed any time soon!

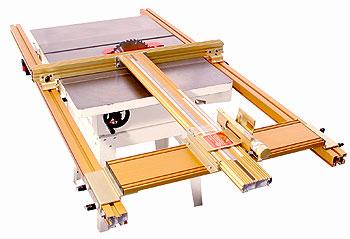

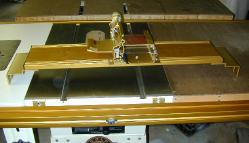

Yes the Incra TS-III is high tech and a design departure from

traditional fences but it is also rock solid, accurate, versatile, expandable, and

a joy to use. Couple those attributes with the great customer service reputations

of Incra and its distributors like Woodpeckers and you have a complete package which

is hard to beat.

If I've piqued your interest, please read on. As usual with my

reviews I will strive to supplement the text with pictures depicting all aspects

of the installation and use of the product. You can then make an informed purchase

decision and not be surprised by anything included in the box. You can click on

any picture to enlarge it.

Index:

Before you Buy

Let's get the only bad news

out of the way right now. Probably the only drawback to the TS-III is the space

it requires. This is not an issue for me but it may be for someone with a very small

work area. Even though the right hand rip capacity is 32", because of the innovative

design of the TS-III, you will need approximately 65" to the right

of your saw's cast table if you want to utilize the full rip capacity of this

fence system.

Let's get the only bad news

out of the way right now. Probably the only drawback to the TS-III is the space

it requires. This is not an issue for me but it may be for someone with a very small

work area. Even though the right hand rip capacity is 32", because of the innovative

design of the TS-III, you will need approximately 65" to the right

of your saw's cast table if you want to utilize the full rip capacity of this

fence system.

What's in the box:

When you receive your TS-III fence it will arrive in three boxes.

One box contains the 72"-long rails, a second contains the Ultra 2/32, and

the third the fence and mount. They all arrived at the same time and without

damage.

When you receive your TS-III fence it will arrive in three boxes.

One box contains the 72"-long rails, a second contains the Ultra 2/32, and

the third the fence and mount. They all arrived at the same time and without

damage.

The picture (left) displays all the parts,

hardware and instructions. Speaking of hardware, I'll say it now and will

probably iterate it again further down, Incra does a great job packaging their hardware.

The picture (left) displays all the parts,

hardware and instructions. Speaking of hardware, I'll say it now and will

probably iterate it again further down, Incra does a great job packaging their hardware.

The fence system itself is constructed almost entirely from extruded aluminum. All

parts, with the exception of the hardware, are finished in an attractive gold colored

anodizing. The fit and finish is excellent and there are no sharp corners or burrs.

As

one would expect all pieces of hardware are listed in their excellent instructions

but the unexpected surprise is that they individually package the hardware by assembly

step. So while you're reading the instructions you see statements like; "use

the 6 10-32 screws from the Ultra mounting hardware kit". For the most

part each hardware pack was consumed before needing to open the next one.

As

one would expect all pieces of hardware are listed in their excellent instructions

but the unexpected surprise is that they individually package the hardware by assembly

step. So while you're reading the instructions you see statements like; "use

the 6 10-32 screws from the Ultra mounting hardware kit". For the most

part each hardware pack was consumed before needing to open the next one.

Installation:

While there are more parts than a traditional fence, the installation

is fairly easy.

|

It's a good idea to skim through the instructions before starting, Yea, I know it's not in our nature but it will make things go easier. :) |

The first step is to locate the

rail mounting brackets (six are included) and the mounting bracket hardware kit.

For my installation only 4 brackets are needed. Using the included hardware, mount

the brackets on the front and rear table edge. The instructions call for the brackets

to be 1/4" below the top of the table and in the photo (left) you can see that

I'm using a rule to measure the distance. This precision is not necessary because

in the next step, we will make the final adjustments for your saw so eyeballing

it is fine (see tip above about reading ahead). At this time you also loosely fit

the rail mounting hardware to each bracket. The hardware pack contains a variety

of nuts, bolts and washers so you should be able to find the correct hardware for

your particular saw.

The first step is to locate the

rail mounting brackets (six are included) and the mounting bracket hardware kit.

For my installation only 4 brackets are needed. Using the included hardware, mount

the brackets on the front and rear table edge. The instructions call for the brackets

to be 1/4" below the top of the table and in the photo (left) you can see that

I'm using a rule to measure the distance. This precision is not necessary because

in the next step, we will make the final adjustments for your saw so eyeballing

it is fine (see tip above about reading ahead). At this time you also loosely fit

the rail mounting hardware to each bracket. The hardware pack contains a variety

of nuts, bolts and washers so you should be able to find the correct hardware for

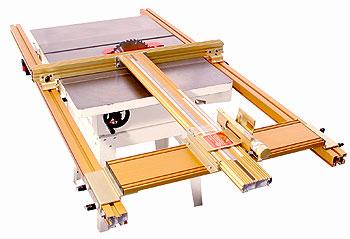

your particular saw. With the brackets installed it's time to mount the

rails. Slide the front and rear rail onto the brackets making sure that the side

with the T-slot on the bottom faces into the saw. With both rails mounted, temporarily

center them on the saw and tighten the hardware.

With the brackets installed it's time to mount the

rails. Slide the front and rear rail onto the brackets making sure that the side

with the T-slot on the bottom faces into the saw. With both rails mounted, temporarily

center them on the saw and tighten the hardware. To set the final mounting bracket height, Incra

cleverly uses the base clamp as a gauge. You simply clamp the 4 base clamps to the

rail at each bracket location and adjust each mounting bracket (as shown at left)

until the base clamps are flush with the table top. This method of alignment worked

flawlessly and doesn't require you to measure anything which if you're like me is

a plus and greatly reduces the chances for error. Once you have tightened up the

brackets, you can loosen the rail mounting bolts and move the rails into their final

position. Simply move the rails so that they extend 7" out from the edge of

the left extension wing and re-tighten the rail mounting bolts.

To set the final mounting bracket height, Incra

cleverly uses the base clamp as a gauge. You simply clamp the 4 base clamps to the

rail at each bracket location and adjust each mounting bracket (as shown at left)

until the base clamps are flush with the table top. This method of alignment worked

flawlessly and doesn't require you to measure anything which if you're like me is

a plus and greatly reduces the chances for error. Once you have tightened up the

brackets, you can loosen the rail mounting bolts and move the rails into their final

position. Simply move the rails so that they extend 7" out from the edge of

the left extension wing and re-tighten the rail mounting bolts. In

preparation for assembling the base mount assembly and the Ultra Jig, locate the

Rail Hardware pack, assemble per instructions, and slide the hardware onto the rails.

In

preparation for assembling the base mount assembly and the Ultra Jig, locate the

Rail Hardware pack, assemble per instructions, and slide the hardware onto the rails.

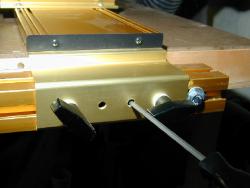

At

this point you will want to tighten down all your knobs as well as the set screws

(left). Also move your stop washer (right) snug up against the right side of the

base clamp. This will allow you to exactly reposition your base assembly if you

have to move it for some other operation.

At

this point you will want to tighten down all your knobs as well as the set screws

(left). Also move your stop washer (right) snug up against the right side of the

base clamp. This will allow you to exactly reposition your base assembly if you

have to move it for some other operation.

Ok, we're coming down the home stretch now!

(left) Grab the carriage and insert it into the base and align the fence end up

with the right side rail brackets. Then loosely attach the fence (right) to the

carriage.

With the fence resting on the supplied cardboard spacers, attach the front and rear

glides. The front glide has a knob on it. These glides include an anti lift hook

which we will discuss later on.

Final Calibration:

While following the Incra instructions you will see an "Important"

note which briefly discusses saw blade/miter slot alignment and the reader is instructed

to consult his saw's owners manual for the details of the alignment. Being safety

conscious myself I felt a bit uneasy about the TS-III alignment procedure because

it makes a few assumptions. The first assumption is that all saws come with an alignment

procedure for blade to miter alignments. Because I know that my Jet Contractors

saw did not include the instructions, I performed some limited research and found

that some Jet and Powermatic saws do not include this procedure in their manual.

That same research indicated that almost all responders who had performed a blade/miter

alignment had aligned the blade to the LEFT slot. This leads to the second

assumption by Incra which is that the miter slots are parallel or that everyone

aligns to the RIGHT slot. In a perfect world the reader would have performed the

blade/miter slot alignment, the miter slots would be parallel, and exactly following

the Incra instructions would result in a perfect setup and that will probably be

the case most of the time.

Having said that it is my belief that the rip fence should always be aligned to

the blade and even though I followed Incra's instructions, I finished up with a

check and a tweak between the blade and the fence.

Move

the fence until it lines up with the right miter slot and engage the micro-adjuster

by pushing the lever down(left). Use the micro-adjuster and a straight edge to align

the fence to the slot. Check both the front and rear of the fence. When you think

you have it, lock the carriage and make sure the fence is still aligned. You may

have to do this a couple of times to get things perfect.

Move

the fence until it lines up with the right miter slot and engage the micro-adjuster

by pushing the lever down(left). Use the micro-adjuster and a straight edge to align

the fence to the slot. Check both the front and rear of the fence. When you think

you have it, lock the carriage and make sure the fence is still aligned. You may

have to do this a couple of times to get things perfect.

Once

you've set the fence to the slot, double check your alignment by checking a tooth

at the front of the saw, then rotate the blade and use that same tooth to check

the rear of the saw. Here I'm using a piece of paper as a gauge to check the fit

since my son walked off with my feeler gauges.

Once

you've set the fence to the slot, double check your alignment by checking a tooth

at the front of the saw, then rotate the blade and use that same tooth to check

the rear of the saw. Here I'm using a piece of paper as a gauge to check the fit

since my son walked off with my feeler gauges.

Once

you are comfortable with the alignment, if needed, unlock the fence and use the

micro-adjuster to set the fence to just "kiss" the blade and lock the

fence. We can now Zero the TS-III.

Once

you are comfortable with the alignment, if needed, unlock the fence and use the

micro-adjuster to set the fence to just "kiss" the blade and lock the

fence. We can now Zero the TS-III.

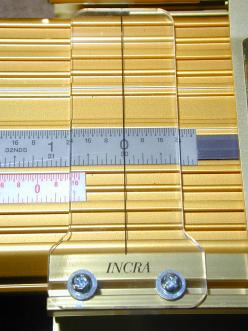

Simply move the magnetic steel rule until it reads zero under the pointer. We're

almost finished.

The

last step in the Zeroing process it to align the micro-adjuster cursor to zero by

loosening the screws and sliding the plastic cursor until the zero mark lines up

with the knob. Next rotate the white micro-adjuster scale until it reads zero under

the cursor. In the photo at right the scale needs to be rotated until the "0"

aligns under the cursor.

The

last step in the Zeroing process it to align the micro-adjuster cursor to zero by

loosening the screws and sliding the plastic cursor until the zero mark lines up

with the knob. Next rotate the white micro-adjuster scale until it reads zero under

the cursor. In the photo at right the scale needs to be rotated until the "0"

aligns under the cursor.

Done!

The whole process including taking some pictures for this review, adapting my existing

extension tables, and running out to the hardware store for the missing screws took

an afternoon. The assembly was straight forward and at no time were the instructions

inadequate or difficult to use.

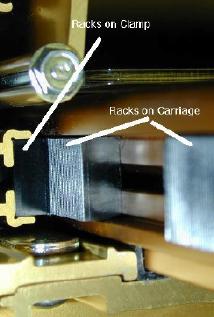

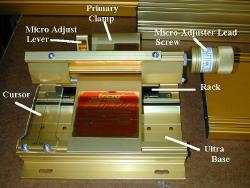

Why would a woodworker be attracted to the Incra TS-III? It has

to be its accuracy and precision. Incra utilizes patented saw tooth racks

which are manufactured in precise 1/32" increments. What does this mean

to us? It means that if your project's dimensions are measured in 1/32"

increments or larger then the TS-III will allow you to easily set the position

of the fence and easily return to that position with .001" accuracy.

If you need to be more precise than 1/32" you can use the Micro Adjuster

which has a scale with .001" increments.

Why would a woodworker be attracted to the Incra TS-III? It has

to be its accuracy and precision. Incra utilizes patented saw tooth racks

which are manufactured in precise 1/32" increments. What does this mean

to us? It means that if your project's dimensions are measured in 1/32"

increments or larger then the TS-III will allow you to easily set the position

of the fence and easily return to that position with .001" accuracy.

If you need to be more precise than 1/32" you can use the Micro Adjuster

which has a scale with .001" increments. The

racks are attached down the far side of the carriage and secured by screws.

They are made from plastic and carry a lifetime warranty from Incra. In the

included instruction sheets, which are excellent if I haven't already mentioned

it, are directions for alignment of the racks in case you ever have to replace

one. According to Incra this is a very rare occurrence.

The

racks are attached down the far side of the carriage and secured by screws.

They are made from plastic and carry a lifetime warranty from Incra. In the

included instruction sheets, which are excellent if I haven't already mentioned

it, are directions for alignment of the racks in case you ever have to replace

one. According to Incra this is a very rare occurrence. This feature allows you to accurately and repeatably move the fence

by rotating the adjuster. It has a scale which has graduations that represent

a .001" movement of the fence. This feature is not to be confused with

the micro adjusters on some other after market fences which are really designed

to eliminate the "bumping" of the fence to set its position. There

is no "bumping" of the TS-III. Chris Taylor of Incra set me straight

on its function. When I first used it I was trying to use it just like the

adjuster on my Vega fence and I couldn't figure out how Incra could make their

claims of repeatability when I was moving the adjuster (and therefore the

rack alignment) all over the place. The correct usage is that during normal

fence operation the woodworker will only use the micro-adjuster to "Zero"

the fence during calibration and usually not use it again unless you need

to get more precise than 1/32". In that case you have to return the adjuster

back to zero when you're finished.

This feature allows you to accurately and repeatably move the fence

by rotating the adjuster. It has a scale which has graduations that represent

a .001" movement of the fence. This feature is not to be confused with

the micro adjusters on some other after market fences which are really designed

to eliminate the "bumping" of the fence to set its position. There

is no "bumping" of the TS-III. Chris Taylor of Incra set me straight

on its function. When I first used it I was trying to use it just like the

adjuster on my Vega fence and I couldn't figure out how Incra could make their

claims of repeatability when I was moving the adjuster (and therefore the

rack alignment) all over the place. The correct usage is that during normal

fence operation the woodworker will only use the micro-adjuster to "Zero"

the fence during calibration and usually not use it again unless you need

to get more precise than 1/32". In that case you have to return the adjuster

back to zero when you're finished. The included 32" stainless steel scale is your primary reference

for setting the position of the fence. It has to be accurate because the racks

are accurate and if it wasn't your measurements would appear to be off. The

TS-III's accuracy comes from the racks and not the scale. I performed an experiment

where I set the scale for "0" and them moved the fence so that I

could see how close it was at the 32" mark. I purposely aligned the cursor

a little off when I pulled the clamp to tighten it down. The racks pulled

the fence so that it locked dead on 32".

The included 32" stainless steel scale is your primary reference

for setting the position of the fence. It has to be accurate because the racks

are accurate and if it wasn't your measurements would appear to be off. The

TS-III's accuracy comes from the racks and not the scale. I performed an experiment

where I set the scale for "0" and them moved the fence so that I

could see how close it was at the 32" mark. I purposely aligned the cursor

a little off when I pulled the clamp to tighten it down. The racks pulled

the fence so that it locked dead on 32". The Incra TS-III can be secured by up to three clamps. The first

clamp which is the one used all the time is right behind the cursor. Setting

this clamp locks and squares up the fence. For light duty ripping this is

all that is needed. The second clamp is located on the front end of the fence

and clamps the fence to the front rail. The third clamp is similar to the

front clamp albeit it requires the hex tool to engage. It provides not only

extra rigidity for those times when you are cutting large, heavy sheet goods

but also becomes and anti-lift clamp to enable you to safely utilize feather

boards and anti kickback rollers, etc.

The Incra TS-III can be secured by up to three clamps. The first

clamp which is the one used all the time is right behind the cursor. Setting

this clamp locks and squares up the fence. For light duty ripping this is

all that is needed. The second clamp is located on the front end of the fence

and clamps the fence to the front rail. The third clamp is similar to the

front clamp albeit it requires the hex tool to engage. It provides not only

extra rigidity for those times when you are cutting large, heavy sheet goods

but also becomes and anti-lift clamp to enable you to safely utilize feather

boards and anti kickback rollers, etc.

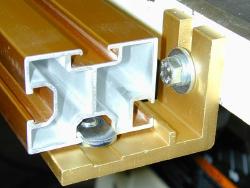

Since this is a review about a table saw fence I thought I had better

show a few pictures of the actual fence. Its dimensions are roughly 36"

long by 1 3/4" wide by 2 3/8" tall. As you can see in the photos

there is a 1/4" T-slot along the face, two in the top, and two on the

back side. The fence face on the TS-III is just as it was extruded but the

new TS-IIIa has a machined flat face. I see nothing wrong with the extruded

face.

Since this is a review about a table saw fence I thought I had better

show a few pictures of the actual fence. Its dimensions are roughly 36"

long by 1 3/4" wide by 2 3/8" tall. As you can see in the photos

there is a 1/4" T-slot along the face, two in the top, and two on the

back side. The fence face on the TS-III is just as it was extruded but the

new TS-IIIa has a machined flat face. I see nothing wrong with the extruded

face.

Hold on to your wallet because once you've installed and used this

fence and visited Woodpecker's

web page you're gonna want to add some other goodies like extension wings,

router fences, joinery packages and more! At right you see the Woodpecker's

Router Table Extension Wing (RTEW) and the Incra Wonder Fence which will be

the subject of my next review.

Hold on to your wallet because once you've installed and used this

fence and visited Woodpecker's

web page you're gonna want to add some other goodies like extension wings,

router fences, joinery packages and more! At right you see the Woodpecker's

Router Table Extension Wing (RTEW) and the Incra Wonder Fence which will be

the subject of my next review.

In these two photographs you'll

see me working the Micro Adjuster and locking the fence using the primary

clamp. It is interesting to note that using the TS-III requires you to focus

your attention to the right end of the saw and look at the Ultra Jig assembly

when setting up for a cut. With traditional fences we seem to have the blade

and fence still within our focus while setting the distance of the fence.

It doesn't matter that we can't see that blade to fence relationship while

looking at the scale, it's just different and requires a few minutes to get

used to.

In these two photographs you'll

see me working the Micro Adjuster and locking the fence using the primary

clamp. It is interesting to note that using the TS-III requires you to focus

your attention to the right end of the saw and look at the Ultra Jig assembly

when setting up for a cut. With traditional fences we seem to have the blade

and fence still within our focus while setting the distance of the fence.

It doesn't matter that we can't see that blade to fence relationship while

looking at the scale, it's just different and requires a few minutes to get

used to.

Miscellaneous stuff:

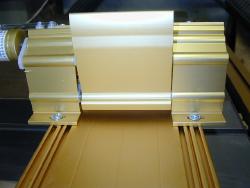

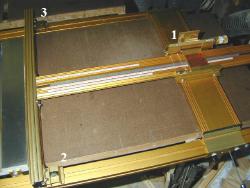

I

mentioned earlier that I had to adapt my existing extension tables to mount

with the TS-III. The left side extension table was pretty simple. I utilized

the mounting brackets that Incra supplied but you can easily make your own.

Simply mount an "L" bracket to the T-track on the front and rear

rail and use them to support your table. The rear was a bit more difficult

because I had to move the table away from the rear of the saw to provide the

clearance required to allow for the base assembly to be positioned anywhere

along the length of the rails. To accomplish this I just cut a piece of 1/2"

birch plywood and used some leftover hardware to attach the new plywood bracket

to the rear rail (left). Then I simply moved the extension table out far enough

to provide the clearance needed (right). This brings to light an inconvenience

for the woodworker with an outfeed table. Repositioning the TS-III requires

access to the rear of the table saw. You may have to use an allen wrench instead

of the hex driver (I did) to secure or loosen the set screws. If you don't

have an outfeed table yet but plan on making one, you should consider making

it free standing so that you can drag it out of the way when repositioning

the TS-III.

I

mentioned earlier that I had to adapt my existing extension tables to mount

with the TS-III. The left side extension table was pretty simple. I utilized

the mounting brackets that Incra supplied but you can easily make your own.

Simply mount an "L" bracket to the T-track on the front and rear

rail and use them to support your table. The rear was a bit more difficult

because I had to move the table away from the rear of the saw to provide the

clearance required to allow for the base assembly to be positioned anywhere

along the length of the rails. To accomplish this I just cut a piece of 1/2"

birch plywood and used some leftover hardware to attach the new plywood bracket

to the rear rail (left). Then I simply moved the extension table out far enough

to provide the clearance needed (right). This brings to light an inconvenience

for the woodworker with an outfeed table. Repositioning the TS-III requires

access to the rear of the table saw. You may have to use an allen wrench instead

of the hex driver (I did) to secure or loosen the set screws. If you don't

have an outfeed table yet but plan on making one, you should consider making

it free standing so that you can drag it out of the way when repositioning

the TS-III.

Testing:

I don't have much to show you in the way of pictures for this part

of the review except for the one at left of me ripping a piece of plywood.

What I wanted to determine at this point was how well the fence was going

to remain in alignment after some use, repositioning and removing and replacing.

I don't have much to show you in the way of pictures for this part

of the review except for the one at left of me ripping a piece of plywood.

What I wanted to determine at this point was how well the fence was going

to remain in alignment after some use, repositioning and removing and replacing.

The first thing I did was remove and replace the fence and carriage from the

jig a couple of times. Each time I locked it down on zero and checked it's

alignment and position to the blade. Everything remained in alignment.

The next test was to loosen the base clamp knobs and completely remove the

assembly including the fence and carriage in one piece and place it down on

a bench. I then slid the clamp hardware into position near the stops I had

previously installed so that I could use the fence on the left side router

wing. After placing the fence assembly back on the rails and getting all the

knobs tightened down moved the fence up next to the blade and checked the

alignment. It was perfect.

The last test in this series was to again remove the fence assembly and reposition

it back up against the stops where it was originally installed. This time

I was not only going to check alignment but I wanted to check and see if the

fence was still "zeroed" to the blade. Again alignment was perfect

as well as the zero. During all of this I was paying attention to how the

carriage was sliding along the rails and I felt no noticeable difference,

another indication that everything was remaining in alignment.

The final test I performed was to use my 36" steel rule and measure the

fence alignment to the right miter slot at 15" and 31". Unlike traditional

fences the TS-III does not change it reference point for alignment as you

reposition it. All other fences rely on the rail position as their reference

so if it's bowed of warped it can affect the fence, especially at the far

end. As I expected the TS-III's alignment was perfect.

Ultimately the only way to tell how well the TS-III will hold up is with time

and use. It is my belief that as long as you always use the front infeed clamp

there should be no reason for the fence to get out of alignment. If you don't

use the clamp then you run the risk of whacking it with a piece of wood and

either bending something or causing it to move.

Conclusion:

The TS-III is easy to install and performs exactly as advertised.

You will quickly fall in love with the positive action of the racks and the

ease by which you will be able to set an accurate, repeatable fence position.

The fit and finish was outstanding as there was not a single surface scratch

on my unit. There are a couple of minor annoyances, the worst of which will

be the time you spend looking for the hex driver or acquiring missing hardware

(Chris Taylor of Incra assures me that missing hardware is a very rare occurrence).

As I stated right up front, the downside is the space it requires but if you

have the real estate, I don't think you will be disappointed.